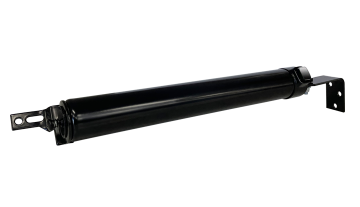

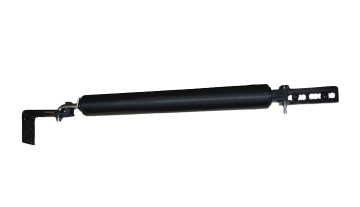

Using 3D printing, the team at Alspec have created a bespoke sliding door system to meet the high end specifications required for a client’s project.

Alspec’s R&D team have utilised the latest in 3D printing technology to develop a bespoke sliding door system to meet a client’s exacting requirements.

The challenge issued to the R&D team was to provide a high performance sliding door which could be proven to meet three key specifications – water penetration, wind load and disabled access:

- Water penetration: Window manufacturers are required under the Building Code of Australia to produce windows and doors that meet specifications set out in the Australian Standard AS2047 – Windows and external glazed doors in buildings. This standard includes water penetration and wind pressure testing. For this project the doors were required to meet 700 pascal (Pa) testing.

- Wind load: Wind load is the intensity of pressure windows or doors can withstand and Alspec products all carry a certified rating. Given the high-rise aspect and coastal location of the project site, the doors needed to cope with the potential for extreme wind loads up to a pressure of 7.8 kPa.

- Disabled access: To provide appropriate access for people with disabilities, the sill design had to meet Australian Standard AS1428.1 – Design for Access and Mobility. The flush sill gives building users a continuous accessible path when travelling between internal and external floor finishes.

Given this combination of specifications was not currently met by any products on the market, the team put together a design solution they believed would meet all three criteria. By using 3D printing technology, they created a model which could communicate the final design to the client in advance. This gave them both a visual and a physical appreciation of how the final product would look and operate, prior to cutting the final dies.

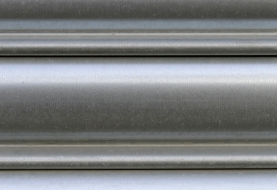

The end product was extruded in structural alloy 6106 T6, a higher grade of alloy which also ensured the project’s higher specification needs were met.

For more information on how Alspec R&D can assist with your next project, contact your local Alspec Branch. You can also read more detailed information on our R&D capabilities here.

View the 3D printer in action